|

| |

MK dual coupler and Pull-pull

Personally I prefer to use one normal size servo (up front) for the elevator

instead of the option with two smaller ones back in the tail. There are

several reasons for this, here are some:

- The bigger servo's are more reliable and robust

- The total weight are equal or lower (long wires are surprisingly heavy)

- It's generally better to have as much weight as close to the CG as

possible, not at the far extremes of the airframe.

With the servo up front there are several methods to connect the servo to the

elevator, I prefer to use the dual-couplers from MK. As they come the concept

involves a long pushrod from the servo to the coupler, and while this makes for

a precise and strong connection I have some bad experience with severe elevator

trim change as a result of changing temperatures. To avoid this I have

been using pull-pull wires between servo and coupler. Below are pictures

and descriptions of how I do it.

|

Here

are all the parts that goes into the tail, since the MK coupler comes with a

one-sided arm only I make my own double arm from fiberglass board. I use a CNC

router, but manual labor with basic tools should to the job also.

|

|

The

double arm are screwed and glued to the center part of the MK coupler

|

|

The

connections between the wires and links are easy to make; just bend the metal

rod around a steel pin, cut it, solder it together and cut threads.

|

|

The

threads are being cut.

|

|

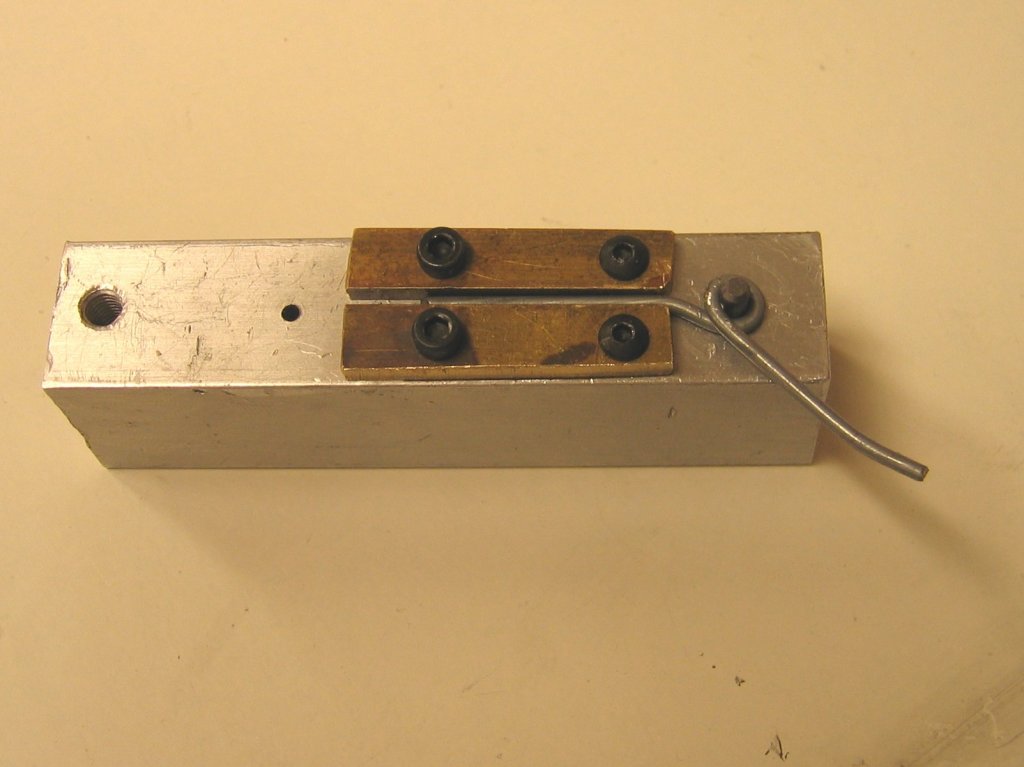

The

four connections are ready to be installed. I keep two of them adjustable,

while the two that ends up in the tail of the airplane has the link soldered in

place. Take a not of the tubes to be crimped onto the wire, they are from

copper not brass. Brass is not really suited for this as brass is brittle

and tend to crack when crimped, copper on the other hand is softer and actually

hardens from the mechanical work of being crimped in place. When they are

crimped in place I secure it with CA-glue just to be double sure that this will

not come loose.

|

|

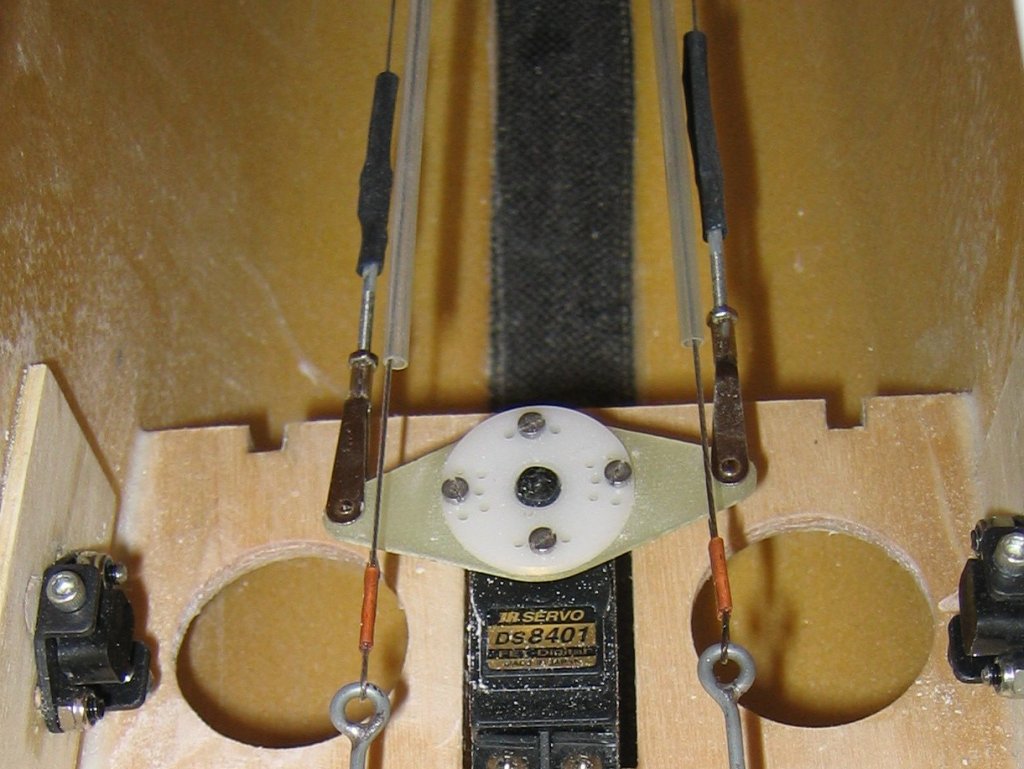

Everything

is in place, here seen ate the servo. To reduce wear I have the connection

between wire and link inside a shrink-tube. This may not be so important

anymore as the engine vibrations that used to destroy everything is not present

in a electric powered model.

|

|